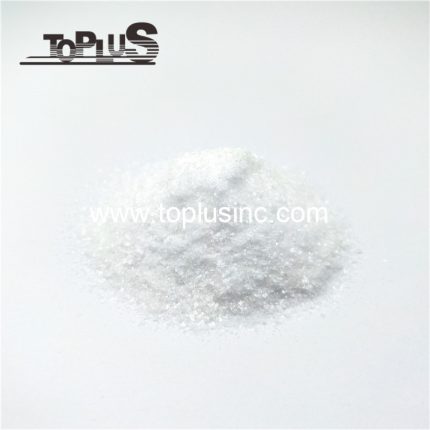

Refractory Grade Calcined Alumina

ОПИСАНИЕ ПРОДУКТА

Молекулярная формула:

Кас №:

Изображений:

Описание

Refractory Grade Calcined Alumina has a wide range of applications in this industry due to its high temperature resistance. As a high-performance material, calcined alumina plays an important role in the refractory industry.It can be used not only for shaped refractory materials, but also for the improvement of unshaped refractory materials.

The following is an introduction to its detailed uses and functions:

1. Increase the refractory temperature: Refractory grade Calcined Alumina has high temperature resistance, which can increase the refractory temperature of refractory materials. And is often use for high-temperature kilns, etc.

2. Improve the performance of refractory materials: calcined alumina fills the pores of refractory materials, increases the volume density, greatly improves the heat resistance, reaches the ideal state of thermal performance, and significantly increases its own strength.

3. Extend the service life of refractory products: calcined alumina has strong activity. In the ball milling deep processing, adding an appropriate amount of dispersant can enhance its fluidity, thereby improving the performance of the castable, enhancing the cohesion of the refractory material, and playing the role of a binder. At the same time, it has a great improvement in high temperature resistance and can extend the service life of refractory products.

4. Improve castable performance: Calcined alumina has the characteristics of small particle size and good fluidity and dispersion, which can improve the performance of castables.

5. Refractory bricks and thermal insulation materials: Calcined alumina is also use for produce refractory boards, refractory bricks and thermal insulation materials, which play an important role in thermal insulation in smelting furnaces

In summary, calcined alumina plays a vital role in the field of refractory materials. It can not only improve the high temperature resistance and mechanical strength of the material, but also extend the service life of the product. It is one of the indispensable important materials in modern industry.

Запрос цитаты

Скачать спецификацию продукта

Даю согласие на обработку персональных данных и согласен с пользовательским соглашением и политикой конфиденциальности

Сельскохозяйственные материалы

Сельскохозяйственные материалы Керамические материалы

Керамические материалы Электронные материалы

Электронные материалы Металлургические материалы

Металлургические материалы Новые энергетические материалы

Новые энергетические материалы Нефтехимические материалы

Нефтехимические материалы Обработка поверхности

Обработка поверхности