HGM

PRODUCT DESCRIPTION

Molecular Formula:

Hollow Glass MicrospheresPurity:

/Cas No.:

65997-17-3Einecs No.:

/Synonym:

HGMImages:

Description

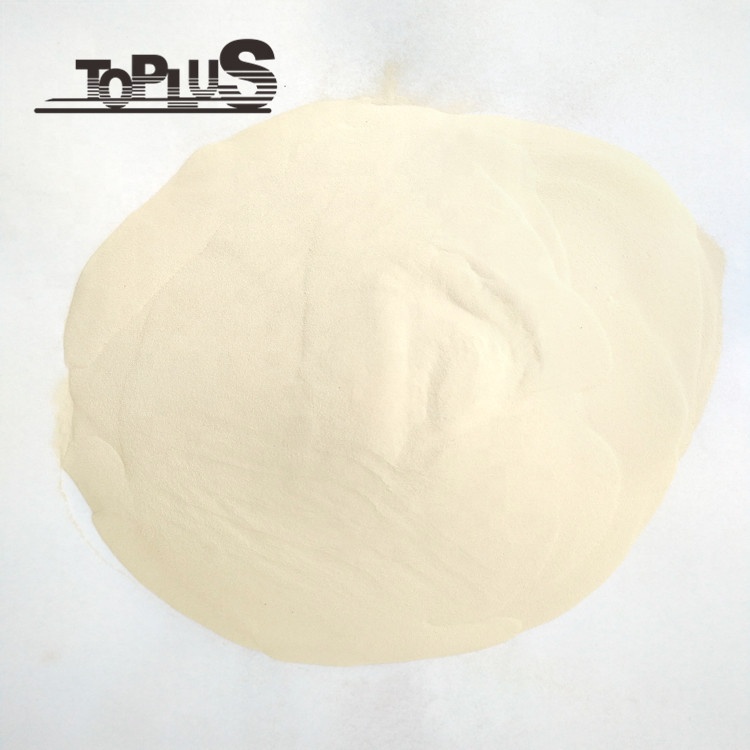

HGM are a type of special process glass microspheres, characterize their lower density and thermal conductivity compare to solid glass microspheres. Developed in the 1950s and 60s, they are a novel lightweight material at micron level, primaril compose of borosilicate. They typically have a particle size of 10-250 μm and a wall thickness of1-2 μm. HGM known for their high compressive strength, high melting point, high electrical resistivity, low thermal conductivity and low thermal shrinkage, earning them the title of “Space Age Material” for the 21st century.

Hollow glass microspheres (also as hollow glass spheres) are a type of micro-sized, hollow spherical powder. The particle size can choice between 30-100 microns as, with a density of 0.1-0.7 g/ml. They characterize their light weight, large volume, low thermal conductivity, highive strength, good dispersibility, fluidity, and stability. Additionally, they offer excellent performance in insulation, self-lubrication, soundproofing,-hygroscopicity, fire resistance, corrosion resistance, radiation resistance, and non-toxicity. This product can direct fill into most types of thermetting and thermoplastic resin products, helping to reduce product weight, lower costs, eliminate internal stress in products, ensure dimensional stability, and provide high compressive impact resistance, fire resistance, sound and heat insulation, and electrical insulation! It can also replace some expensive fillers like light diffusers, bronze powder, mbdenum dioxide, and silica gel.

Hollow glass microspheres have significant weight reduction and sound insulation effects, providing good resistance to cracking and ease ofprocessing. They widely use for in engineering plastics, anti-corrosion and insulation materials, rubber, buoyancy materials, fiberglass, artificial marble, artificial onyx and wood substitutes, as well as in fields such as oil industry, aerospace, 5G communication, new high-speed trains, automotive and marine applications, heatulating coatings, and adhesives. They have greatly promoted the development of China’s science and technology.

Request a Quote

Download product spec

I consent to the processing of personal data and agree with the user agreement and privacy policy

Agricultural Materials

Agricultural Materials Ceramics Materials

Ceramics Materials Electronic Materials

Electronic Materials Metallurgy Materials

Metallurgy Materials New Energy Materials

New Energy Materials Petrochemical Materials

Petrochemical Materials Surface Treatment

Surface Treatment